Scan Management: Difference between revisions

| Line 7: | Line 7: | ||

A linear scan is a simple 2-axis scan where one axis moves along a scan line, and the other steps a small amount each line, thus creating a rectangular raster scan image. A linear scan works with any two pairs of axes in a system (including Turntables/Rotators). | A linear scan is a simple 2-axis scan where one axis moves along a scan line, and the other steps a small amount each line, thus creating a rectangular raster scan image. A linear scan works with any two pairs of axes in a system (including Turntables/Rotators). | ||

<br clear="all"/> | |||

[[File:LinearMultiStep.PNG|thumb|right]] | [[File:LinearMultiStep.PNG|thumb|right]] | ||

| Line 14: | Line 15: | ||

The path for the step motion can be defined either with a contour or defining the shape of the part using the "Define Part" option. | The path for the step motion can be defined either with a contour or defining the shape of the part using the "Define Part" option. | ||

<br clear="all"/> | |||

[[File:LinearSurface.PNG|thumb|right]] | [[File:LinearSurface.PNG|thumb|right]] | ||

| Line 19: | Line 21: | ||

A linear surface scan is used when both the Scan and Step motion involve multiple axes, e.g. scanning an asymmetrical surface such as a fan blade. A surface must be defined using Teach-and-Learn or other methods. | A linear surface scan is used when both the Scan and Step motion involve multiple axes, e.g. scanning an asymmetrical surface such as a fan blade. A surface must be defined using Teach-and-Learn or other methods. | ||

<br clear="all"/> | |||

== Tray == | == Tray == | ||

| Line 37: | Line 40: | ||

== Timed == | == Timed == | ||

= Scan Options = | = Scan Options = | ||

Revision as of 14:29, 30 October 2025

Scan Management is handled by the Scan Manager control or by the Scan settings group in the Basic Mode Main Controls window.

Scan Types

Linear

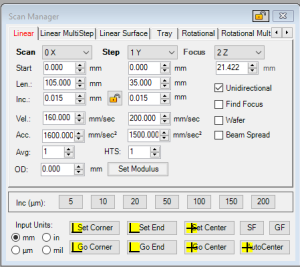

A linear scan is a simple 2-axis scan where one axis moves along a scan line, and the other steps a small amount each line, thus creating a rectangular raster scan image. A linear scan works with any two pairs of axes in a system (including Turntables/Rotators).

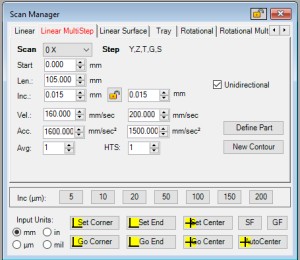

Linear MultiStep (ODIS-NDT only)

A linear MultiStep scan is where a scan axis moves in a linear path, but multiple axes may be involved in the step motion. For example, scanning up a wedge shape involves a single scan axis (X) but multiple step axes (Y and Z).

The path for the step motion can be defined either with a contour or defining the shape of the part using the "Define Part" option.

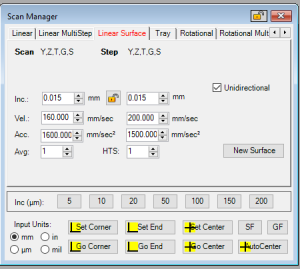

Linear Surface (ODIS-NDT only)

A linear surface scan is used when both the Scan and Step motion involve multiple axes, e.g. scanning an asymmetrical surface such as a fan blade. A surface must be defined using Teach-and-Learn or other methods.

Tray

A tray scan is a type of scan where multiple parts are arranged in a regular grid. The tray scan can skip the regions between parts when scanning. Commonly used for scanning JEDEC trays of parts.

Rotational (ODIS-NDT only)

If a Turntable or Rotator is present in the system, a Rotational scan can be performed where the turntable/rotator moves constantly, while a step axis increments every rotation.

Rotational MultiStep (ODIS-NDT only)

A rotational multistep scan performs a constant rotation on a turntable/rotator, with a step motion that involves multiple axes. For example, scanning a nose cone may involve Y, Z and Gimbal motion.