Transducer Characterization

Transducer characterization is the procedure wherein the signal of a transducer is tested for beam spread, peak frequency, and other tests. By characterizing a transducer, the user can determine if is operating according to specifications. Repeated testing over time will tell the user how the characteristics are changing, and if the transducer needs to be replaced.

There are two features that can be used to evaluate your transducer: a simple Transducer Report (which uses the scope and FFT), and a Beam Profile scan.

Note: Beam Profile scans are only available when using ODIS in Advanced Mode or by using the stand alone Beam Profile software.

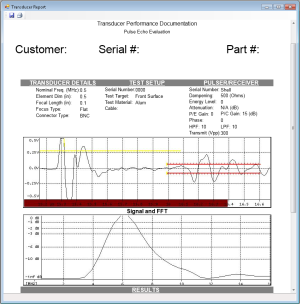

Generating Transducer Reports

A user may generate simple Transducer Reports by pressing the “Transducer Report” button in the top toolstrip of the main form:

This will generate a report with the current A-Scan display, FFT, digital Pulser/Receiver (if any) and other relevant info. The user manually enters a serial number. The part # is pulled from the “Transducer Details” section of the Session Information window. Other information from the Session Information window is also pulled into the transducer report.

The user can add his own logo and an electronic signature by adding two files to the directory where ODIS is installed:

- customerlogo.jpg

- customersignature.jpg

These files will be added to the report the next time it is generated.

The report can be saved as HTML or text data, or printed directly to the printer if desired.

Generating Beam Profiles

A Beam Profile scan collects data along three axes in order to generate a profile of a transducer’s beam spread and focus point. Typically, the Beam Profile is performed on a ball target or a thin wire in order to get a clean result.

The collection uses the first available data gate to collect the results. If no data gate is present, Beam Profile will fail.

The typical beam profile procedure is as follows:

- Move the transducer until it is just over a ball target. It should be as close to the target as possible.

- The Beam profile will first do a collection along the Z (DAC) axis, moving away from the part. This generates a profile of the Focus position.

- Next, the beam profile will move the Z (DAC) axis back to the detected Focus position, and then move the X axis in a pass over the target. This gives the beam spread at focus along the X Axis.

- Finally, the beam profile will move the Y-Axis over the target. This gives the beam spread at focus along the Y Axis.

- After all scans are done, a report is generated.

Preconfiguring the Z (DAC) axis

Since part of the beam profile involves moving a transducer away from a small target, it is important to make sure the Z-axis will move in the correct direction, and that the Water Velocity is set correctly.

By default, the Z-axis will move in the positive direction (e.g., DAC start + DAC length). This assumes that positive motion on the Z-axis brings the transducer up, and negative motion moves it down. If your Z-axis direction is reversed, click on the “Reverse DAC Direction” checkbox on the Beam Profile tab.

The Water Velocity and Gate Tracking direction must be set correctly in the Configuration in order for the gates to follow the varying focus while the Z-axis. To confirm that gates are tracking properly, click on the “Track Focus” button on the digital oscilloscope, and then slowly move the Z-axis. You should see the gates move in the same direction as your signal.

If the gates move in the opposite direction of your signal, check on the “Reverse Gate Tracking direction” checkbox in ODIS configuration (this is found on the Focusing tab). If your gates are tracking in the right direction but are moving ahead or behind the signal, check your Water Velocity. Note that water temperature can affect the water velocity.

Setting up Beam Profile

Note: To Create a beam profile, the user must be in Advanced mode (See User Management and ODIS Run Modes).

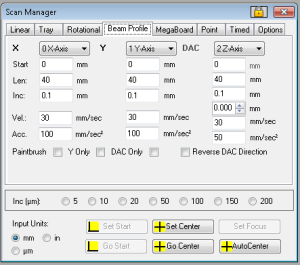

To start a beam profile scan, select the Scan manager and click on the “Beam Profile” tab.

The Scan is set up similarly to any linear or tray scan, with some extra options.

- Paintbrush: if this item is checked, the beam profile will be performed on the X-Axis only. A special Paintbrush report is used to generate the resulting report.

- Y Only: if this item is checked, the beam profile will be performed on the Y-Axis only. A special Y-Only report form is used to generate the resulting report.

- DAC only: if this item is checked, the beam profile will be performed on the Z (DAC) axis only. A special DAC-only report form is used to generate the resulting report.

- Reverse DAC direction: reverses the direction of the Z-Axis (DAC) when performing a beam profile. See PreConfiguring the Z (DAC) axis.

- Offset (Up/down control on the DAC only): This adds an offset to the reported Z-Axis (DAC) position when generating the report. This takes into account any extra offset required when measuring the focus position.

The start position is always the center of the target. The DAC length represents the distance to move away from the target when doing the DAC profile. The X and Y lengths are the total amount of travel over the target: for example, if the X-Axis target is centered at 10 mm and the X length is set to 20 mm, the X-Axis will move from position 0 mm to position 20 mm.

The increments are the desired spacing between samples on each curve. It is recommended that the user keep the velocities reasonably slow for the best coverage. If the Beam Profile is performed too quickly, values may be skipped and the result will look “sawtoothed”, rather than a smooth curve.

Performing a Beam Profile Scan

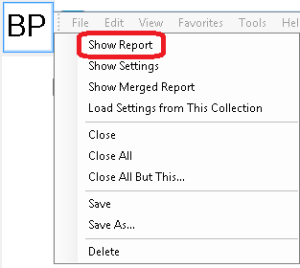

Just before starting, the user should have the transducer centered over the target and as close to it as possible. The scan start should be established at this point. To start the scan, press the “Start Scan” button as with any scan. No image will be displayed during the scan. The scan progress can be monitored in the bottom right of the main form just like any other scan. Depending on your settings, the user should see anywhere from 1 to 3 scan lines. When the scan is finished, an icon with a “BP” will appear in the Image icon bar at right.

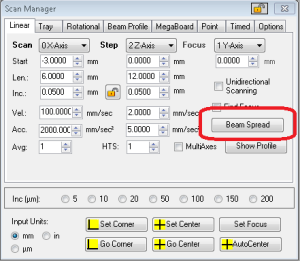

Generating a Beam Spread image from a Beam Profile

If desired, an image of the Beam Spread can be generated using the settings from the Beam Profile. In order to perform this scan, do the following:

- Select the "Linear" tab of the Scan Manager dialog.

- Press the "Beam Spread" button. This will copy the appropriate settings from Beam Profile into the Linear Scan:

- The Scan axis will be set to "X"

- The Step axis will be set to "Z"

- Scan dimensions will be set to the "X" settings

- Step dimensions will be set to the "DAC" settings

- The Scan Start position will be set to the X position minus one half the X distance.

- The Step Start position will be set to the DAC position.

- Adjust your gate length so that it will cover the range of time the signal covered during the Beam Profile. Optionally, Add a long Follower gate and have the Data Gate track the Follower. The latter is recommended as it will reduce the amount of extraneous signal from data multiples.

- Start the scan. (Note: it is important that the user NOT press "Set Center" or "Set Corner" before starting the scan, or your scan position will be incorrect and possibly impact your ball target.)

The scan generated will show a representation of the sound field as it leaves the transducer.

Beam Profile Reports

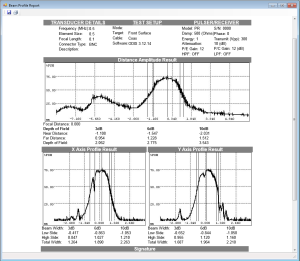

To show the report associated with the Beam Profile, right click on the icon and select “Show Report” from the resulting menu. The report generated for a typical Beam Profile will be displayed. The DAC curve at the top shows the position of the maximum peak from the data gate (and therefore the position of the focus point). The position on the DAC is relative to the focus unless the “Show Axial Results in Absolution Position” checkbox is set (see Configuring Reports), plus whatever Offset is added in the scan setup.

The X and Y Scans show the beam shape across the target at the focus point. The 0 position of the image is the scan start position.

The report also displays any transducer details that were entered on the Session Information page, as well as details for the Digital Pulser/Receiver settings (if any) in the system.

The square with the red “X” is where a customer logo can be placed. (see Generating Transducer Reports).

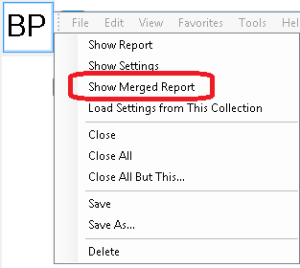

Merging Reports

Multiple reports can be merged into a single result if more than one Beam Profile is loaded. In a Merged report, the single curves are combined into a multi-curve result, with the 0 positions of each result being aligned. This allows for direct comparison of reports.

The merge will use any Beam Profile reports currently loaded. If you do not want to include a report in your merged report, make sure to close it before generating the merged report.

Configuring Reports

Report configuration settings are found in the “Reports” section of ODIS configuration. The settings, report files, images and export data can be adjusted as needed.