Teach and Learn Setup

Teach and Learn allows an operator to define a complex step axis consisting of multiple axes. Using the complex step axis, the user can keep a transducer following a curved surface on a rotational part (such as an hourglass shape or other irregular surface).

Teach and Learn is available for both Rotational Scans and Linear Scans.

Activating Teach and Learn

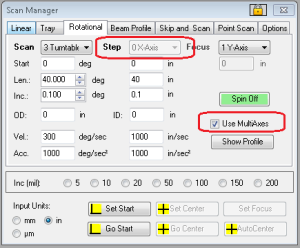

Teach and Learn is available on both the Linear tab or the Rotational tab of the Scan Manager.

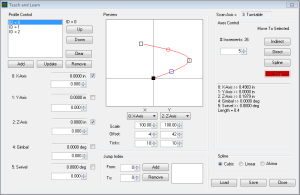

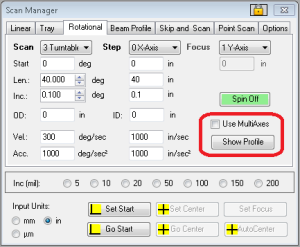

To activate the interface, the user must check the "UseMultiAxes" checkbox. To edit the profile, press the "Show Profile" button. Once pressed, the Teach and Learn interface will be shown.

Note: on a Rotational scan, If no rotational axes are present in the system, this button will not be active.

Teach and Learn Controls

The controls for the Teach and Learn allow the user to set points along a curve and make adjustments as needed.

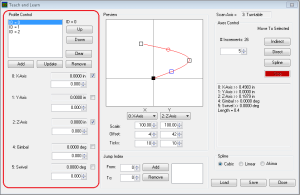

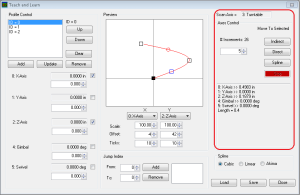

Profile Control

The Profile control is where the user adds, deletes, or adjusts points along the curve. The list of points is shown at the top left. By selecting a point from the list, the position information for that point is shown below. A series of buttons allow the user to add, update, remove, or reorder the points. The button operations are:

- Add

- Adds a new point using the current motor position.

- Update

- updates the selected position with the new motor position information.

- Remove

- deletes the selected position.

- Clear

- deletes all points.

- Up/Down

- changes the order of the collected positions.

The position information for a profile point shows both the Absolute position (relative to the 0 position of the axes), and the Relative position to the previous point. The relative position can be edited: the Absolution position is shown for reference.

Note that the position of the Rotational axis will be excluded since it is used for the Scan, not the Step.

Checkboxes next to the position axes allow the operator to ignore specific axes in a profile: that way, if the axis not needed for the profile but its position is changed during setup, the axis will not move during the actual collection.

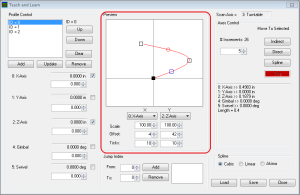

Preview

The Preview section will show a representation of the defined curve using any two of the axes used in the complex step. The axes are selected using the drop-downs just below the profile drawing. There must be at least two defined points for a curve to be shown (five if using Akima Splines).

The profile preview shows several different points of information:

- The black filled rectangle is the point currently selected in Profile Control.

- The black empty rectangles are the remaining profile points.

- The round red circle shows the current motor position.

- The blue rectangle shows the location of an increment as specified in Axes Control.

The size and position of the preview control can be manipulated by the mouse in a similar way to scanned images: right-click on the image to cycle between a zoom (magnifying glass) or pan (hand) icon. The user can pan by left-clicking and dragging on the preview. The user can zoom by left-clicking on the preview and dragging the mouse up and down.

The scale and offset can also be adjusted manually using the numeric inputs just below the preview window.

Axes Control

The Axes Control allows the operator to preview the motion that will be performed when generating the scan. In this way, whether the transducer maintains an acceptable offset and angle from the part can be tested.

Axes control consists of some buttons and a selected increment. The increment is based on the Step Increment as defined in the Turntable scan. The number of increments is simply the overall length of the curve divided by the increment. The user can move the motors to any increment along the curve.

As the increment changes, the blue box on the Preview window will change with it, showing the location of the particular increment on the curve.

Four buttons tell the system how to move to the desired increment:

- Indirect

- Currently not in use

- Direct

- will move the axes from the current position directly to the desired increment. Caution: be sure there is a clear path from the current position to the desired increment, or collisions may occur.

- Spline

- will move the axes from the current position to the desired increment by following the programmed curve. This will take longer than the Direct motion, but is potentially safer on complex curves.

- Stop

- immediately stops all motion if pressed.

Below the buttons, the Absolute positions of the axes at the selected increment will be displayed, along with a Length value. The Length shows the position of the selected increment along the Complex Step, where zero is the start of the spline.

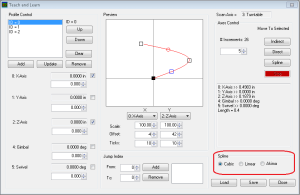

Spline Configuration

There are currently three types of interpolation available in order to generate the curve represented by the defined points:

- Cubic

- performs a cubic spline interpolation, works best on curved surfaces.

- Linear

- does a simple linear interpolation between points.

- Akima

- alternative to cubic splines, may be more accurate but requires more points.

The operator should chose the best interpolation for their application.

Configuring a Complex Step

Fundementally, defining a complex step is a simple two-step process:

- Move the axes to a point along the desired curve,

- Record the point

The user can move the motors with either the Motor window or the function keys while Teach and Learn is active. The motor position will update on the Preview window in real time. Use the Digital Oscilloscope to confirm the the signal returned from your part remains relatively constant in time.

Care should be taken to generate enough points to follow the part surface properly. Use the Preview and the Axes Control to test the motion and confirm that it is as desired.

Once configured, when the user presses the "Close" button, the complex step profile is stored in memory. Profiles are stored as relative positions, so that if a user needs to make and adjustment to the Start position of a rotational scan, the curve should "travel" with the new start position.

Caution:: do not reinitialize, change your scan start, or reset motor positions to zero while generating your complex step axis.

Using a Complex Step

Once a complex step is defined, it will remain in memory until the user exits ODIS. To activate the complex step, check the box labeled "Use MultiAxes" on the Rotational tab of the Scan Manager. Note that when this is active, the Step Axis drop-down list is disabled. Once activated, proceed with a rotational scan in the normal manner.

When the Rotational scan is running, instead of incrementing on a single axes, all of the axes defined along the curve will move simultaneously. The increment defined on the step axis defines the length along the spline to move.

For collections created using the complex step, using the motor cursor to move to a spot on the resulting image will move all the axes involved in the complex step. The motion will attempt to follow the original curve in order to avoid collisions with the part.

Caution: if the user has moved axes off of the original curve (as defined in 3-dimensional space), care must be taken when doing click-and-move motor motion on complex surfaces, as there is still a risk of collision.

Loading and Saving Complex Step Axis Information

The setup information for the complex step will be saved with the parameter file when generated. If the user wishes to save the data to a separate file, use the "Save" button at the bottom of the Teach and Learn window. Complex step information can also be loaded into memory using the "Load" button on the Teach and Learn window.