Rotational Scan

Note: Rotational scans are only available in ODIS-NDT in Advanced Mode.

A rotational scan is a collection performed on an axis that has 360° of motion, such as a turntable or rotator. Collection is continuous and only stops when paused or aborted by the user. The collection may keep the data collected on the entire rotation or only a smaller arc (e.g., 90°).

The Collection can be displayed as an unwrapped cylinder or as a Polar plot, depending on how the original data was collected. 3D display options are also available.

Rotational scans can only be created if there are valid "Turntable" axes defined in Motors.xml. The definition of a turntable axis is:

- 360° specified in the "Length" key.

- Units are specified in degrees (i.e. "deg")

- The "CountsPerRotation" key is defined.

An axis that does not meet all these criteria is not considered a turntable axis. An axis that has these criteria except for the length is considered a Gimbal or Swivel axis.

Rotational Scan Configuration

Since the rate of collection on rotational scans tends to be slower than for Linear scans, it is usually a good idea to turn off Try to use Fast Downloading This prevents timeout errors.

Also useful for rotational scans are the Align to Zero options (see Rotational Scan Alignment below).

Starting a Rotational Scan

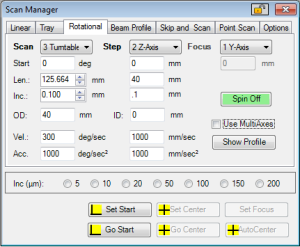

A Rotational scan is started by selecting the "Rotational" tab of the Scan Manager. The user must set the parameters of the Rotational scan using the input fields.

- Scan Axis is automatically set to the first available rotational axis. It can only be changed if there is more than one rotational axis available.

- Step Axis can be any other non-rotational axis (or axes).

- Focus Axis is unused.

- Scan Start position should always be zero for a rotational scan.

- Step Start position is set as desired.

- Scan Length and Increment are specified in degrees unless and Outer Diameter (OD) is specified.

- Step Length and Increment are specified in system units.

- Scan Velocities and Accelerations are always specified in degrees, regardless of the OD setting.

- Step Velocities and Accelerations are in system units.

Once the settings are configured, the user can press the "Start" button on the Main Form to begin the rotational scan. The rotational motion is continuous and will not stop until finished, unless the scan is paused or aborted by the user.

Rotational Scan Options

Auto-Center, Set/Recall Center, and Set Focus are unused or irrelevant for Rotational scans and are disabled.

The direction of the scan and step axes can be reversed on the Options page: thus the rotator can be made to scan Counter-Clockwise instead of clockwise, and vice-versa.

Rotational scans can be paused and resumed.

Testing Rotational Alignment

If the part to be tested is not centered on the turntable or rotator, the water path to the part may vary as it rotates, resulting in loss of signal or excessive gate lengths in order to compensate. By turning on the "Spin" button, the user can rotate the turntable continuously while observing the ultrasonic signal. By determining where the signal is closest to and/or farthest from the transducer, the part position can be adjusted until the time variation is at acceptable levels.

Note: the turntable will spin at the Medium Jog Speed specified in the Configuration dialog.

ID and OD Settings

The Inner Diameter (ID) and Outer Diameter (OD) can be used to show the Turntable length and increment in units that match the step axis. In this way, the user can guarantee that the image dimensions are "square" (e.g. the Scan and Step increment are the same length).

Setting the OD will change the Scan Length and Increment to the equivalent units by calculating the circumference. Setting the OD to zero will revert the Scan Length and Increment to degrees.

The ID setting is used when displaying the rotational scan as a Polar plot: the data is drawn as a circle, with the ID representing the distance from the center to the first scan line, and the OD representing the distance to the last scan line (or vice-versa if the image orientation is flipped vertically). If the ID is zero, the polar plot will start drawing the results at the center of the image.

Multi-Step Scans

A teach-and-learn profile can be generated that allows the system to move multiple axes when stepping. This allows the user to scan rotational parts that have curves or angles (e.g. nose cones, hourglass shapes, etc. The profile can be created and edited from the dialog created when "Show Profile" is pressed.

See Also: Teach and Learn Setup

Rotational Scan Alignment

Motion and triggering are always in integer counts. The number of counts per increment may not be an even multiple of the Turntable resolution, or the Turntable resolution itself may not be an integer value. Therefore, careful setup is required to insure that the rotational scan results are properly aligned. If rotational scans are not properly aligned, the resulting image will appear to "lean" in one direction or another.

The counts per rotation in Motors.xml must be defined as accurately as possible. If it is not a round integer number, make sure to enter a decimal number to as many points of accuracy as required.

Also, if using Encoder Triggering on a Rotational scan, the EncoderResolution parameter must be specified. This is the number of encoder counts per degree. As with the Counts per Rotation, this must be specified as accurately as possible.

Rotational Scans without Alignment

If performing a rotational scan without automatic Zero alignment, the scan must meet the following criteria in order for the image to align:

- The counts per rotation of the motor must be an integer value

- The Scan Increment must be a multiple of the counts per rotation

- The Number of Points per Download must be a multiple of the number of *triggers* per rotation (e.g., the number of points on a single scan line)

As these critera can be difficult to apply without trial and error, ODIS provides two methods for automatic alignment of rotational images.

Software Latching

By turning on Align To Zero and Software Only, the system will attempt to compensate for any rounding errors that may occur due to the desired scan length and increment. The system will calculate where the zero point should be, and adjust the incoming data to align with the zero degree point of the turntable.

Hardware Latching

If using a Galil motor controller and a Servo-based Turntable axis, a Latching function can be used to determine the zero degree point of the turntable. In this case, each time the latch is crossed, a signal is sent to ODIS that tells it where to align the data. The system must be wired to accept the latch input from the turntable motor for this configuration to work properly.

Note that the Latch input is NOT the same as the Home input.