AutoCenter, AutoFocus, and AutoPeak

Basics

AutoFocus, AutoCenter and AutoPeak are tools that help an operator center and focus the transducer on the part to be inspected. All require a proper gate setup in order to operate normally.

- AutoFocus will use the Front Surface Follower to find the Water Path, and gates Data1 or Data2 to focus the signal.

- AutoCenter will use the crossing of the first Follower gate if available. If no Follower gate is present, it will use the first Data gate or RTG gate, and will use the edge crossing of the Absolute Peak Amplitude value.

- AutoPeak will use the the first available Data Gate or RTG Gate on each channel. Does not work on Follower gates.

AutoFocus

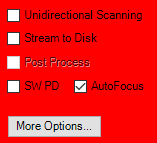

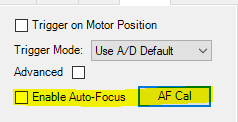

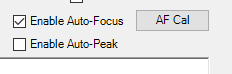

AutoFocus is accessible through the AutoFocus tools window. In Basic Mode, this is found in the Motor tab of the main controls window. In Advanced Mode, it is found on the Options tab of the Scan Manager. To Enable AutoFocus, select the appropriate checkbox on either the main controls window (Basic Mode) or the Scan Manager window => Options tab (Advanced Mode).

Note: The AutoFocus button is only visible if "ShowAutoFocus Tools" is enabled in System Configuration: see below.

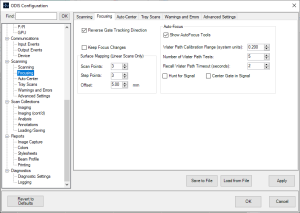

AutoFocus Configuration

There are some configuration options for AutoFocus; these are found in System Configuration->Scanning->Focusing.

- Show AutoFocus Tools

- whether or not to display the button that gives access to AutoFocus setttings.

- Water Path Calbration Range

- This defines in the system units (mm/in) the maximum allowed motion when focusing. So when hunting for a signal, the system will not move the focus any more than +/- this distance. This is to make sure the Focus axis does not collide with a part.

- Number of Water Path Tests

- This is the number of acquisitions that will be used to determine the Water Path. The system takes an average of the values found with each acquisition.

- Recall Water Path timeout

- this is the maximum number of seconds the system can use before it cancels a Water Path search. As with with the calibration range, this minimizes the chance of a collision with the part.

- Hunt for Signal

- if checked, the system will physically hunt for a water path crossing when performing scans. If disabled, the system will only check that a crossing is present before proceeding. for Tray Scans when scanning each part separately, this means that if no signal is found, the part will be skipped.

- Center gate in Signal

- if checked, and a water path crossing is found, the follower or data gate will be centered in the signal before continuing. This adjust the gate position only, not the physical Focus position.

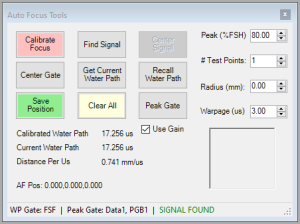

Tools Window

The AutoFocus Tools window allows an operator to configure and test the focus for a part. It is assumed the a part to be tested will be in the scanner. Once AutoFocus is established, it can be used over and over again on the same type of part. For the Auto-Peak tools on the same window, See below.

Note:Many of the buttons will not operate until Calibration has been performed. Do a calibration first.

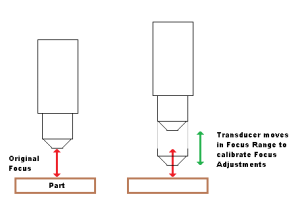

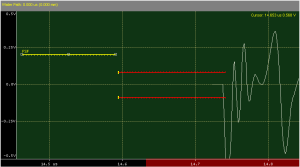

- Calibrate Focus

- This will move the Focus axis for a short distance +/- the original location to determine the signal response. This allows the system to calculate the water velocity and also determine which direction is "towards" the part and which is "away" from the part. A signal *must* be within the Follower gate for this to work. The distance is defined in the Calibration Range in Configuration above.

- In addition, the Calibrated Water Path is recorded to be used for recall.

- Find Signal

- If no signal is currently crossing the Water Path Gate, this will physically move the Focus axis until a signal is found. Uses the Warpage value to determine the maximum distance to move. Focus must be Calibrated first.

- Center Gate

- This will center the Water Path gate within the currently detected water path signal. Does not do any physical motion.

- Get Current Water Path

- Records and displays the current water path.

- Recall Water Path

- Attempts to physically move to the last saved water path, assuming the Follower is currently crossed.

- Save Position

- Saves the current AutoFocus position so it can be used in scans. This will become the predefined Focus position when AutoFocus is enabled for scanning.

- Clear All

- Clears all calibrations and water paths.

- Warpage (us)

- The expected deviation along the part. Used to limit motion when focusing or peaking.

Status Bar Values

The status bar will display information about the current state of calibration.

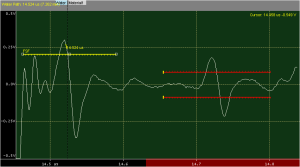

- WP Gate

- Displays the selected Water Path gate. By default, this is the gate named “FSF”. If not found, it will use the currently selected gate.

- Peak Gate

- Displays the selected Peak detection gate(s) when doing Auto Peak. The Peak Gate(s) be set when Peak Gate is pressed. Internally, the gate(s) are set using first available Data or RTG gate on each channel and board, e.g. if using a 2-channel 8xGTe board and Data1 is active on channel A and Data2 is active on channel B, those two gates will be used for peaking.

- SIGNAL FOUND/SIGNAL NOT FOUND

- Shows the state of the Water Path signal the last time an operation was performed.

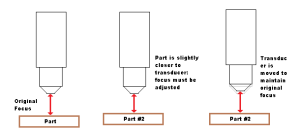

AutoFocus in Linear Scans

When Autofocus is enabled for Linear scans, the system will first move back to the saved AutoFocus position and attempt to recall the water path that was saved in AutoFocusing. If found, it adjusts the Focus of the scan to the desired water path. If not found, the original Focus is used and the scan proceeds.

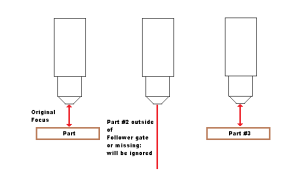

Auto-Focus on Tray Scans

|

When doing a normal tray scan, the Auto-Focus procedure is the same as for a Linear scan (see above). The procedure when collecting individual parts is as follows:

The result is a collection identical to a regular Tray Scan. |

|

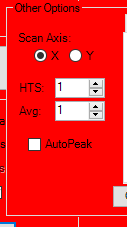

Auto-Peak

Auto-Peak is also accessible on the Auto-Focus Tools window. Auto-Peak uses various techniques to set the peak amplitude of a signal to the desired value. To enable Auto-Peak, check the appropriate box on the main controls window => Other Options (Basic Mode) or the Scan Manager window => Options tab (Advanced Mode).

- Peak Gate

- Attempts to peak the amplitude of the signal within a Data gate. The desired peak amplitude is entered in the “Peak (%FSH)” control. This will be done either by moving the Focus Axis or by adjusting the P/R Gain. The “Use Gain” checkbox will determine whether or not to use motion or P/R gain.

- If using Gain, the AutoPeak will attempt to use the first Data or RTG gate on each available channel, and peak each channel independently by adjusting the gain on the P/R associated with the board and channel.

- If using Motion, the Focus axis is moved +/- the Warpage value and peaks are recorded along with the position at which they were collected. The peak closest to but not exceeding the desired amplitude is selected, and the Focus Axis is moved to the location.

Options

- Peak (%FSH)

- The desired peak value in %FSH.

- Test Points

- Number of XY positions on which to peak. Default is one point. If using Gain for peak, the system will use the average gain adjustment among all points to adjust the pulser. If using Motion, the last valid peak position will be used.

- Radius (mm)

- Spacing between test points. Arranged in a circle around the starting point, e.g. the Center of the part. Points that do not have a detected peak are ignored. If there is only one test point, the radius is ignored.

Status Bar Values

The status bar will display information about the current Auto-Peak state.

- Peak Gate

- Displays the selected Peak detection gate(s) when doing Auto Peak. The Peak Gate(s) be set when Peak Gate is pressed. Internally, the gate(s) are set using first available Data or RTG gate on each channel and board, e.g. if using a 2-channel 8xGTe board and Data1 is active on channel A and Data2 is active on channel B, those two gates will be used for peaking.

Auto-Peak on Linear Scans

Auto-Peak will always take place after Auto-Focus if both are enabled. The procedure varies depending on the user settings:

- If Auto-Focus and Auto-Peak are enabled and Auto-Peak is using motion, Auto-Peak will take place at the Auto Focus position. if no Water Path was found during Auto-Focus, Auto-Peak will be skipped.

- If Auto-Peak is enabled and peaking with gain is enabled, the systems moves to the Scan Center and runs the Auto-Peak process.

Note: Auto-peak will not run on a Patch Scan.

Auto-Peak on Tray Scans

In a normal Tray Scan, the Auto-Peak process is the same as for Linear scans.

if scanning each part separately, the Auto-Peak process will run in the center of each part, using the same procedure.

Auto-Center

AutoCenter allows an operator to find the geometric center of a part and establish the scan center at that point. Optionally, it can also be used to set the scan and step dimensions of a scan. It works by searching for the edges of the part along the Scan and Step axes. Using the points where the signal drops off, the dimensions of the part can be calculated.

AutoCenter Configuration

For AutoCenter to work, a Follower or Data Gate must be crossing an ultrasonic signal. This signal should be lost, or at least outside the gate region, if the transducer is moved past the edge of the part.

If no signal is crossing the gate, AutoCenter will not proceed.

Autocenter uses separate velocities from Scans or jog speeds. In this way an operator can tune the velocity for the best result. The values can be changed in Configuration->Scanning->Auto-Center. Also, an optional return pass can be set with a different (generally slower) velocity.

AutoCenter Procedure

When properly configured, the user should move the transducer to the rough center of the part. Confirm that the ultrasonic signal is present. Then, the user can press the "AutoCenter" button on the Scan Manager Window (Advanced Mode), or the "AutoCenter" or "AutoCenter and Resize" buttons on the main controls window in Basic Mode.

The autocentering procedure is as follows:

- the Scan Axis will move in a positive direction until the signal no longer crosses the gate

- the axis will move back to the original start position.

- the axis will move in the negative direction until the signal no longer crosses the gate.

- the axis will use the difference between the positive and negative signal loss points and move to the middle of the part.

- the procedure repeats with the Step axis.

- the procedure should end with the transducer in the middle of the part.

if "AutoCenter and Resize" was pressed instead of just "AutoCenter", the Scan and Step lengths will be adjusted to match the measurements made by the AutoCenter procedure.

AutoCenter with Tray Scans (Advanced Mode)

In Advanced Mode, additional options are available for Auto-centering when scanning a tray of parts. When each part is scanned individually, AutoCenter can be used on each part, and the operator can choose on which directions to check for edges.

if "Scan Each Part Separately" is disabled, Autocenter Config "AC Cfg" is disabled.

To activate AutoCentering, the user must select the "Tray" tab on the Scan Manager window, and select "Scan Each Part Separately". This will enable the "AC Cfg" (i.e. AutoCenter Config) button.

AutoCenter Configuration Window

The Auto-Center Configuration window will display a grid based on the current Tray Scan setup parameters. Within each grid cell are arrows that indicate the directions in which auto-center will look for edges. Clicking on a cell will rotate through the possible options for edge detection:

- No Centering (clear)

- Left Side Only

- Right Side Only

- Left and Right

- Top Only

- Top and Left

- Top and Right

- Top, Left, and Right

- Bottom Only

- Bottom and Left

- Bottom and Right

- Bottom, Left, and Right

- Top and Bottom

- Top, Left, and Bottom

- Top, Right, and Bottom

- All edges

Padding

Padding specifies how much "extra" space should be added to the scan size, given the edges found in AutoCenter. This has the effect of slightly increasing the scan area for each cell, giving a border on the scanned image beyond the autocenter edges.

Buttons

- Clear All

- Removes all edge detection from all cells.

- Set All

- Sets edge detection for all edges on all cells.

- Cancel

- Closes the dialog without saving settings.

- OK

- Closes the dialog and saves settings.

Validating Autocenter Configuration

The "AC Cfg" button will remain green while the row and column settings of Tray Scan has not changed. If the user changes the number of rows and/or columns in the tray, the "AC Cfg" button will turn red as a warning to the user.