Tray Scan

Tray Scans are used to collect data on an array of regularly-sized parts. Each part can be scanned individually with appropriate focus adjustments, or an entire row can be collected at one time.

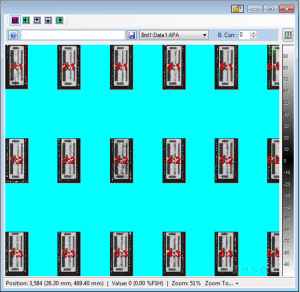

Tray scan results are functionally identical to a Linear Scan, except that the results for each part can be displayed in a grid. Individual parts may also be analyzed by exiting the "Tray View" mode.

When performing a Tray Scan, applying the correct spacing between parts is critical.

Starting a Tray Scan

In Basic Mode, a Tray scan is selected when the "Tray" option is selected on the Scan Settings tab of the Controls form. In Advanced Mode, A Tray scan is started by selecting the "Tray " tab of the Scan Manager. In either case, the user must set the parameters of the Tray scan using the input fields.

- Scan Axis and Step Axis can be any pair of axes. In Basic Mode, they are always the first two linear axes.

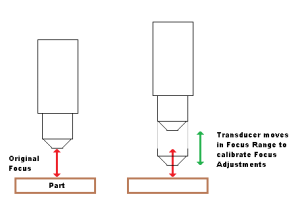

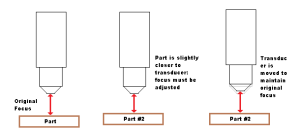

- Focus Axis should be set to the axis that is perpundicular to the surface of the parts being scanned. In Basic Mode, this is always the third linear axis.

- Scan and Step Start positions can be entered manually in Advanced Mode; in Basic Mode, they are set but not displayed.

- Scan and Step Length can be any length that will fit within the scanning tank.

- Scan and Step Increment (or Resolution as displayed in Basic Mode) can be set to any increment less than the Scan and/or Step Length, within the limits of the encoder and/or motor resolution.

- Scan Velocity and Acceleration should be set as high as possible without causing trigger overruns.

- In Advanced Mode, the user can also specify the Step Velocity and Acceleration: in Basic Mode, these are set to maximum.

Once the settings are configured, the user can press the "Start" button on the Main Form to begin the Tray scan.

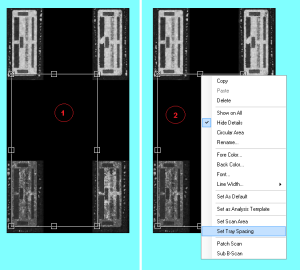

Setting up Tray Size and Spacing

|

The Tray spacing determines how much "space" is between each part. It is important that the spacing be set properly so that the parts are all aligned in the image results, and that the scans do not "drift". Spacing includes the width and/or height of the part: thus if a set of parts that are 10mm x 20mm are arranged so that they are next to each other, the minimum spacing is still 10mm x 20mm. Spacing can be set by typing the desired values into the Scan Setup fields in either Basic Mode or Advanced Mode. By making a coarse scan of a section of the tray, a user can determine tray size and spacing without tedious trial and error. Instead, do the following:

|

Tray Scan Options

Tray Scans have the same options for Unidirectional, Stream to Disk, and HTS as Linear Scans.

Scanning each Part Individually

See Also: Configuration settings for Tray Scans

Location of the option for scanning each part separately (Basic Mode) |

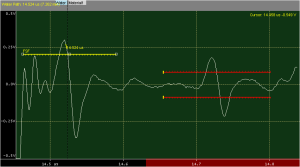

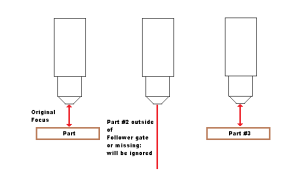

By default, Tray scans scan an entire row at a time. If focusing on each part is critical, the user can set the option of scanning each part individually. If Autofocus is also enabled, the system will focus on the center on each part before collecting data. The process is slower than a normal tray scan, but will maintain a constant focus over each part.

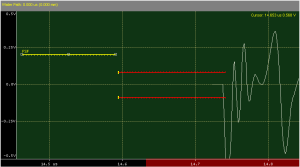

When scanning each part individually, Autofocus calibration and Front Surface Follower position and length are critical. Also, for the procedure to work, there must always be a part in the first row and column of the Tray Scan. The procedure when collecting individual parts is as follows:

The result is a collection identical to a regular Tray Scan. |

|

Identifying Parts

Parts are shown by column and row: to quickly identify the position of a part in your tray, press the "id" button at the top left of the image window. This will show the row/column values for each part in the tray.

Color, Font and Size of the Ids can be changed in the Configuration dialog.

Tray View vs Single Image View

The user can switch between a Tray View of the result (i.e. where all parts are shown in a grid) and a single-image view by pressing the "Tray View" button on the Image Toolbar. When in Tray View, the gray page up/down buttons will switch between each data type (Peak, TOF, etc.). When in Single Image View, the Page Up/Down buttons will switch between the data types of a single part, and the green left/right arrows will change the row and column in order to look at a different part. The image drop-down will also show the row and column values when in Single Image view.