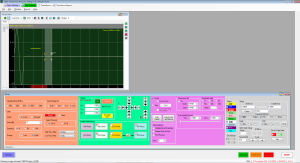

Basic Mode

Basic mode is a simplified version of the ODIS interface for use with 3-axis XYZ Linear or Tray Scan systems using Encoder triggering. The system combines all the common controls in a simple interface for quick setup and control, rather than separate controls.

Using Basic Mode

In order to use Basic Mode, either:

- The system configuration Mode key must be set to basic. This will load the Basic Mode as the default unless the default login mode has been changed.

- A use with the mode set to "basic" must login (See ODIS Security Manager).

Basic Mode Controls

Digital Oscilloscope

The Digital Oscilloscope is identical to the setup found in Advanced mode, with the exception that the A/D and Gates are set in the Instrument Tab on the main Setup window.

Image Windows

Image windows are also identical in setup compared to Advanced mode.

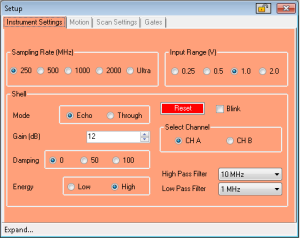

The Setup Window

The main control panel combines Instrumentation settings (A/D and Pulser/Receiver), Motion, Scan Setup, and Gate controls. Controls are clustered into tabs for organization purposes. Instrument Settings

The Instrument Settings tab controls basic A/D settings and Pulser/Receivers. Available settings will change automatically depending on the settings in ODIS_Config.xml.

- Sampling Rate: common native sampling rates plus an ultra mode that upsamples the A/D.

- Input Range: common Input Rates

- P/R: Available Pulser/Receiver settings. A variety of controls will be shown depending on the P/R. Common controls include:

- Mode (usually Pulse-Echo and/or Through Transmission)

- Gain

- Damping

- Energy

- Channel (on multi-channel P/Rs such as the DPR500)

- High Pass/Low Pass Filters (available filters depend on the Pulser)

The Setup window supports up to 4 A/D boards in multi-channel systems. Switching between channels is accomplished by selecting the radio buttons at the top of the control.

Figure 3: Multi-Channel Controls. Names of channels can be set in the Configuration dialog.

Multi-Channel controls appear on other tabs as needed (e.g. Gate Settings).

Figure 3: Multi-Channel Controls. Names of channels can be set in the Configuration dialog.

Multi-Channel controls appear on other tabs as needed (e.g. Gate Settings).

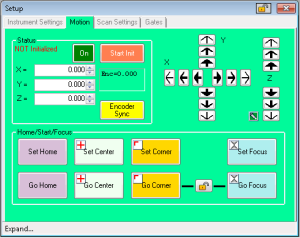

Motor Controls

Motor position readouts, initialization, and start/corner position settings are set on the Motor Controls tab.

Status Region

The Status region displays current position, whether or not an axis is at a limit, and allows the user to initialize motors or perform a manual encoder synchronization. To the right are the manual motion controls for an X-Y-Z scanner. Motion can also be controlled using the function keys, as with Advanced mode.

Limit strikes are noted by the red text just above the motor positions. Note that the direction of the limit is displayed with the trailing + or - after the axis name.

The Start Init button will start a standard Initialization. The "Encoder Sync" button will set the current X-Axis Motor position to the Encoder Position, resynchronizing the motor to the encoder in case of a power loss or other problem. Synchronization can also take place automatically using the Configuration settings.

Home/Start/Focus

Home positions and The Scan Center or Scan Corner positions are set using the buttons in this region. All the Sets use the current position. Positions can be recalled using the "Go" buttons.

The "lock" button between the "Go Corner" and "Go Focus" buttons sets whether or not the Focus is automatically recalled when returning to Center or Corner.

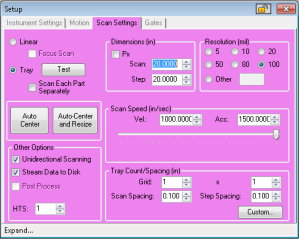

Scan Settings

Scan Options

- Unidirectional scanning (the Scan Axis will collect in only one direction),

- Stream Data to Disk (data will be written directly to disk rather than kept in memory).

- HTS allows the operator to "skip" lines in the scan, in order to speed up the overall time. If greater than 1, each step will increment the specified number of lines and fill the skipped lines with the data from the previous scan.

Linear Scans

Figure 5: Linear Scan Setup

The Scan Settings tab configures the scan settings for Linear or Tray Scans. Scan Dimensions, Resolution, and Speeds are configurable, as well as some basic options For Linear scans, the "Linear" radio box should be selected. The X-Y Scan dimensions are set in the "Dimensions" region using system units. Pre-selected resolutions or a custom resolution may be entered in the "Resolution" region. Resolution applies to both the X and Y dimensions.

The operator can set the scan velocity manually or using the slider bar in the Scan Speed region. The speeds apply to the Scan (X) axis only. Step speed is set automatically. Just under the Scan Type selection, the "Auto-Center" buttons allow the user to automatically center on a part. Gates must be set before attempting an Auto-Center. The "Auto-Center" button centers on the scan without changing any settings. "Auto-Center and Resize" will center, and use the results to set the Scan dimensions.

Options available for Linear Scans

- Do Focus Scan allows the user to perform multiple Linear scans at different foci, in order to find the best water path for a particular part.

When the scan is started and the "Do Focus Scan" option is selected, a dialog box will appear, allowing the user to 1) Set the number of Focus scans to create, and 2) Set the increment between foci. Note that it is VERY important to confirm that the scans will not collide with the part. The dialog will warn the user of such.

Figure 6: Focus Scan Dialog Box It is possible to reverse the direction of the Focus Scan increment by putting a negative number in the "Other" increment.

Tray Scans

With Tray Scans, a new region for setting the Tray Count and Spacing appears. The Scan Spacing represents the distance from one edge of a part to the same edge on the next part (and thus includes the full scan dimension).

Options for Tray Scans

- Scan Each Part Separately becomes available when a Tray Scan is selected. In this mode, each chip in a tray is scanned separately.

Gates

See Also: Gates and Regions, Gate Features

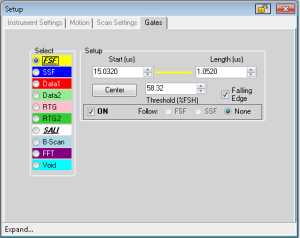

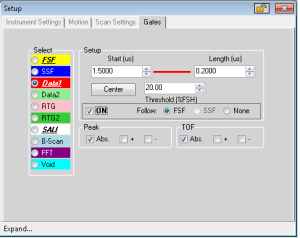

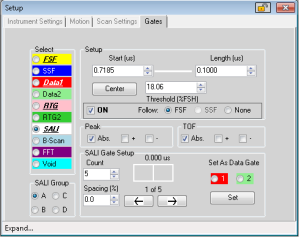

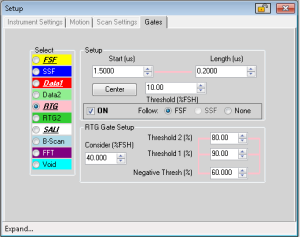

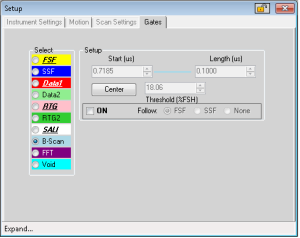

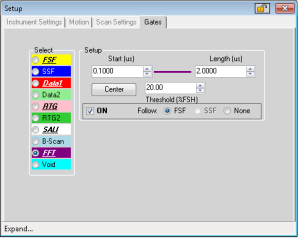

Gate Setup is done on the last tab. Gate Settings are set per channel. The Channel selection radio buttons are therefore visible on this tab. Basic Mode gate setup allows for one Front Surface Follower, one Sub-Surface Follower, two Data Gates, one Relative Threshold Gate (if supported by the A/D board), SALI Gates, and one tracking B-Scan gate.

Gates are activated by checking the "Active" checkbox just below the main setup. A gate can be centered on the scope using the "Center" button.

Gates can be dragged and resized on the scope, the same as Advanced mode. Changes on the scope will be reflected in the Gates tab.

Gate setup is slightly different depending on the type of gate being selected.

Follower GateA Follower Gate setup includes start, length (in microseconds) and threshold (in %FSH). The Front-Surface follower cannot be set to track another gate, but the Sub-Surface follower can be set to track the Front-Surface Follower if needed. |

|

Data GateA Data gate setup is similar to a Follower gate. A gate to track can be selected using the radio buttons (if the appropriate follower gate is active), or be set to track no gate. A sub-section of gate features can be activated: +/- Peak, +/-TOF, Abs Peak/TOF, Void, and PCM Delamination Detection. Additional features can be added by pressing the "More" button. |

|

SALI GateSALI Gate setup shows an extra region where the user can set the number of SALI gates and the spacing between the gates. Spacing is applied in % of the SALI gate width. SALI gate overlap is achieved by entering a negative spacing. A display between the Count and the Spacing shows how the SALI gates overlap (if at all). |

|

RTG GateFor A/D boards that support it, a Relative Threshold gate can be configured. The extra region allows the user to set the Consider for Delam threshold, and the positive and negative Relative thresholds for the RTG Gate. |

|

B-Scan GateThe B-Scan gate setup is almost identical to the Follower gate, with the exception that the gate can be set to follow either the Front-Surface or Sub-Surface follower. B-Scan gates have no threshold. |

|

FFT GateThe FFT Gate defines a region used to generate an FFT. FFT gates have no threshold. |